Our 3D Printing Technologies

We specialize in two cutting-edge 3D printing technologies: FDM and SLA. Each offers unique advantages for different applications and materials.

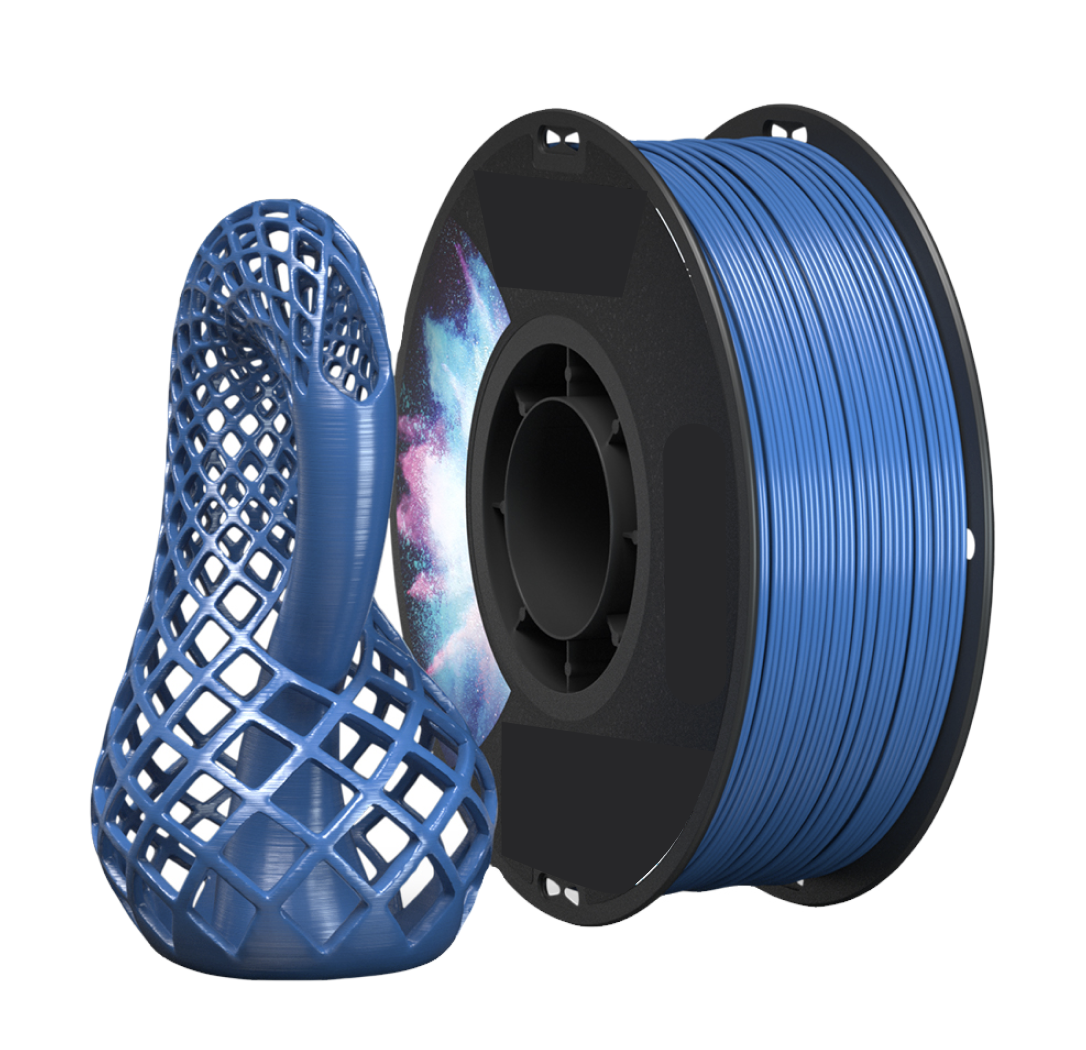

FDM (Fused Deposition Modeling)

FDM technology builds parts layer-by-layer from the bottom up by heating and extruding thermoplastic filaments. It's ideal for creating durable prototypes, end-use parts, and complex geometries.

Engineering Grade Materials

| ID | Class | Material | Applications |

|---|---|---|---|

| 1 | Lite | PLA | Concept Modelling, Prototype Tooling & Functional Testing |

| 2 | Lite | PLA PRO | Concept Modelling, Prototype Tooling & Functional Testing |

| 3 | Lite | ABS | Concept Modelling, Prototype Tooling & Functional Testing |

| 4 | Lite | PETG | Concept Modelling, Prototype Tooling & Functional Testing |

| 5 | Lite | PC | Concept Modelling, Prototype Tooling & Functional Testing |

| 6 | Lite | ASA | Concept Modelling, Prototype Tooling & Functional Testing |

| 7 | Max | PLA | Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality. |

| 8 | Max | PETG | Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality. |

| 9 | Max | PETG ESD (Electrostatic Discharge) | Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality. |

| 10 | Max | PC | Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality. |

| 11 | Max | PC-FR | Nano-reinforcement technology, to deliver exceptional mechanical properties and printing quality. |

| 12 | Flex | TPU 90 (Shore - 90A) | Perfect solution for applications where high flexibility and durability are required. |

| 13 | Flex | TPU 95 (Shore - 95A) | Perfect solution for applications where high flexibility and durability are required. |

| 14 | Flex | TPU 95 WR (Shore - 90A) (WEATHER RESISTANCE) | Perfect solution for applications where high flexibility and durability are required. |

| 15 | NYLON/ POLYAMIDE | NYLON 6 | Deliver engineering properties intrinsic to Nylon |

| 16 | NYLON/ POLYAMIDE | NYLON 6 - GF (STIFF) | Deliver engineering properties intrinsic to Nylon |

| 17 | NYLON/ POLYAMIDE | NYLON 6 -CF (RIGID) | Deliver engineering properties intrinsic to Nylon |

| 18 | NYLON/ POLYAMIDE | NYLON 12 - LMS (Low Moisture Sensitivity) | Deliver engineering properties intrinsic to Nylon |

| 19 | Exotic | Smooth PLA (Mould Like) | Unique filaments for unique applications |

| 20 | Exotic | PLA Wood | Unique filaments for unique applications |

| 21 | Exotic | PC- ABS | Unique filaments for unique applications |

| 22 | Exotic | Castable | Unique filaments for unique applications |

Mechanical Properties

Tensile Properties

Heat Resistance (°C)

Applications

Prototyping, End-use parts, Functional testing, Manufacturing aids, and more.

Poly Latic Acid (PLA)

PLA

Acrylonitrile Butadiene Styrene (ABS)

ABS

Polyethylene terephthalate glycol (PETG)

PETG

FLAME RETARDANT ABS (ABS-FR)

ABS-FR

PLA+ Carbon Fiber (PLA+CF)

PLA+CF

PETG+ Carbon Fiber (PETG+ CF)

PETG+ CF

Polymethyl Methacrylate (PMMA)

PMMA

Polyoxymethylene or Acetal (POM)

POM

Acrylonitrile Styrene Acrylate (ASA)

ASA

Polycarbonate (PC)

PC

Polypropylene (PP)

PP

Polycarbonate + Acrylonitrile Butadiene Styrene(PC+ABS)

PC+ABS

High Impact Polystyrene (HIPS)

HIPS

Polyvinyl Alcohol (PVA)

PVA

Thermoplastic Elastomers (TPE)

TPE

Thermoplastic Polyurethane (TPU)

TPU

Aluminum (Metal Fill PLA)

Aluminum

Brass (Metal Fill PLA)

Brass

Bronze (Metal Fill PLA)

Bronze

Copper (Metal Fill PLA)

Copper

WOODFILL

WOODFILL

Glow In Dark

Glow In Dark

CERAMIC

CERAMIC

SLA (Stereolithography)

SLA technology uses a laser to cure and solidify liquid resin, creating highly accurate and detailed parts. It's perfect for producing smooth, high-resolution prototypes and parts with intricate features.

SLA Materials

| ID | Name | Application |

|---|---|---|

| 1 | Standard Resin | Part Prototyping & Testing |

| 2 | Clear Resin | Transparent parts |

| 3 | Tough Resin | Durable and sturdy parts |

| 4 | Flexible Resin | Parts to have Very high elongation & great impact resistance |

| 5 | Dental Resin | Ideal for surgical and dental appliances |

| 6 | Ceramic-Filled Resin | Excellent for heat resistance |

| 7 | Water-Washable Resin | Parts can be dyed or painted easily for various applications |

Standard Resin

Standard Resin

Clear Resin

Clear Resin

Tough Resin

Tough Resin

Flexible Resin

Flexible Resin

Dental Resin

Dental Resin

Ceramic-Filled Resin

Ceramic-Filled Resin

Water-Washable Resin

Water-Washable Resin

Why Choose HyCube Works?

- Wide range of materials for diverse applications

- Expertise in both FDM and SLA technologies

- High-quality, precise 3D printed parts

- Customizable solutions for your specific needs

- Fast turnaround times and professional support